Ensuring quality expectations are met efficiently.

Manufacturers of advanced PCB (printed circuit boards) assembly know that simultaneously producing cost competitive products and meeting the quality expectations of customers are vital to their success.

Perfect for accurate PCB inspection

In the intricate task of PCB manufacturing, reliable inspection and measurement of different connections, vias and clearances is paramount during and after production. Microscopes are utilized in PCB inspections to enable users to improve quality and increase output. The Mantis inspection microscope is used in FAI (First Article Inspection), which is a requirement to ensure that the first product produced is 100% correct. In our industry, we need to ensure that the first off from the SMT assembly line is perfect before running the rest of the batch.

World-class innovation

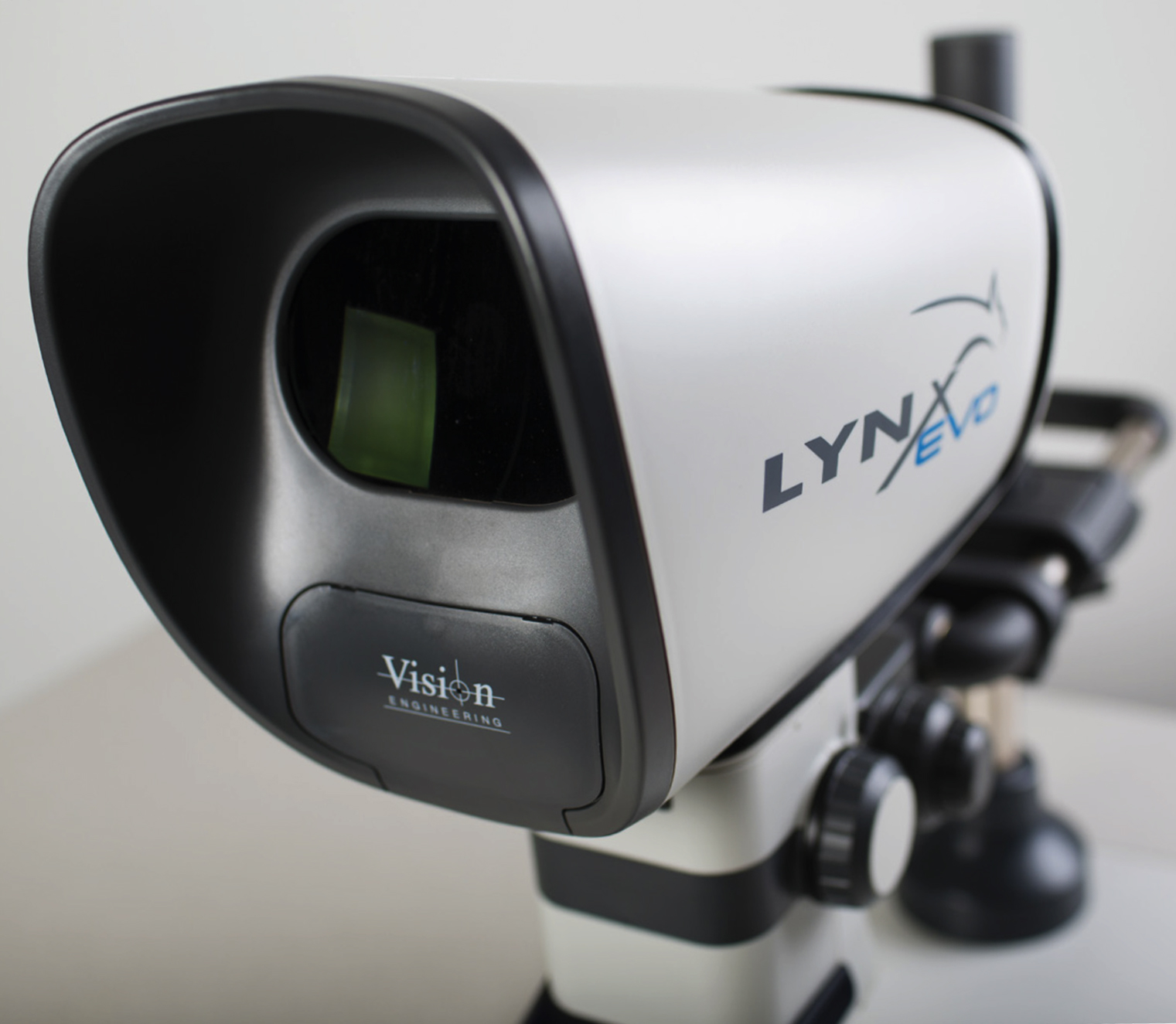

Vision Engineering has been leading the world with pioneering technology and award-winning innovations since 1958. In 2020 we were recognised by the Queen’s Award for Innovation, for our Lynx EVO high magnification, stereo eyepiece-less microscope. Now and in the years ahead, we will maintain an unswerving commitment to innovation, ergonomic design and improved user productivity.

The Vision Engineering advantage

Everything that we make is designed with ergonomics and ease of use in mind. It’s what sets us apart. We know that if a microscope can be used comfortably, the operator will be more comfortable, happier and more productive. Accuracy, speed and throughput are all improved with Vision Engineering’s unique ergonomic designs.

Lynx Evo

Work better, for longer, with this award winning ergonomic stereo microscope.

Mantis

Eyepiece-less 3D stereo microscope offering exceptional operator comfort and superb 3D imaging.