Fast, accurate and consistent measurement and inspection for aerospace manufacturers

Our range of non contact metrology and award-winning ergonomic microscopy equipment supports the essential manufacturing processes of high value products, such as aerospace parts and satellite components, giving you confidence that they will perform reliably and consistently to the highest standards.

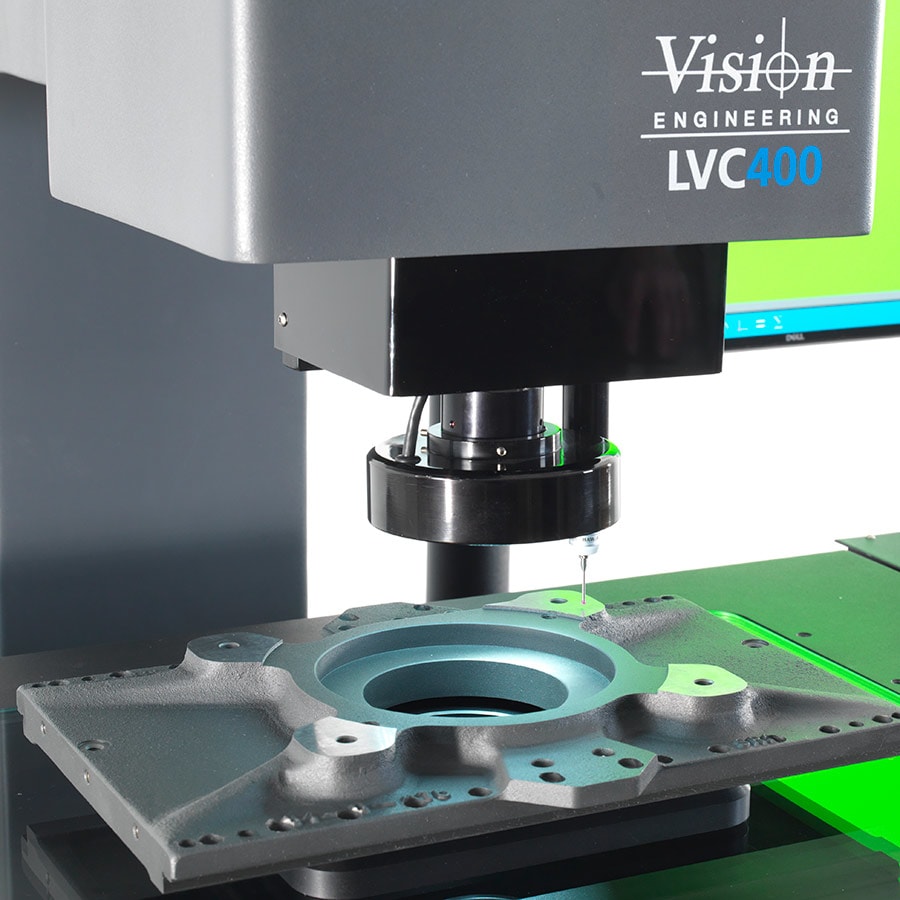

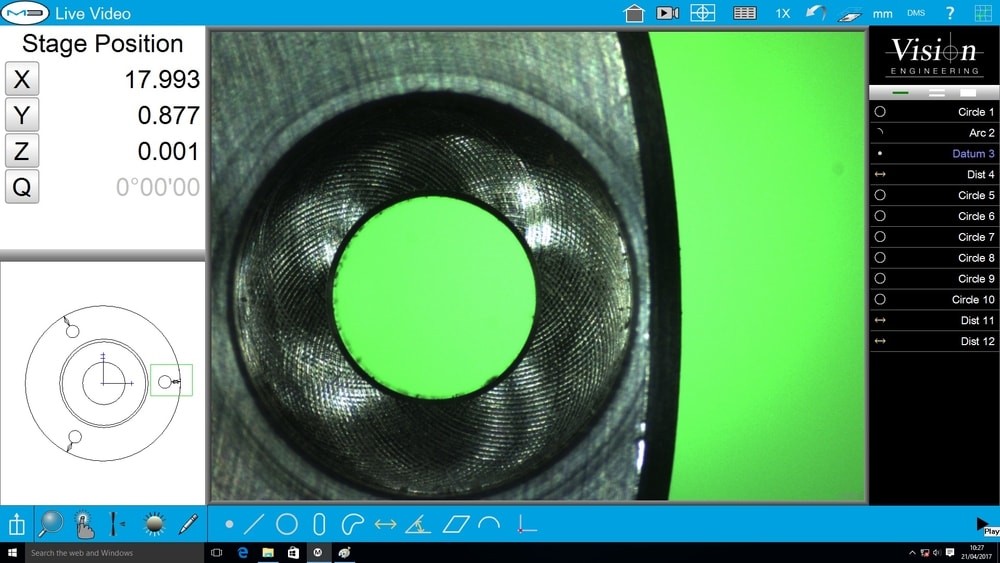

Fully automated 3-axis measuring

Vision Engineering’s LVC fully automated 3-axis measuring systems have the power and versatility to meet the demanding needs of aerospace manufacturers and suppliers. Suitable for subjects of up to (400 mm x 300 mm x 200 mm), they are ideal for measuring large components or, just as easily, batches of small components.

Faster production workflows

LVC promotes greater productivity and faster workflows in the aerospace supply chain by automating time-consuming measuring and inspection processes. Its motorised measuring stage and zoom lens work together for fast, consistent accuracy that you can depend upon. What’s more, the multi-position zoom lens allows changes to the magnification to be part of measurement program, eliminating the need for time-consuming manual changes.

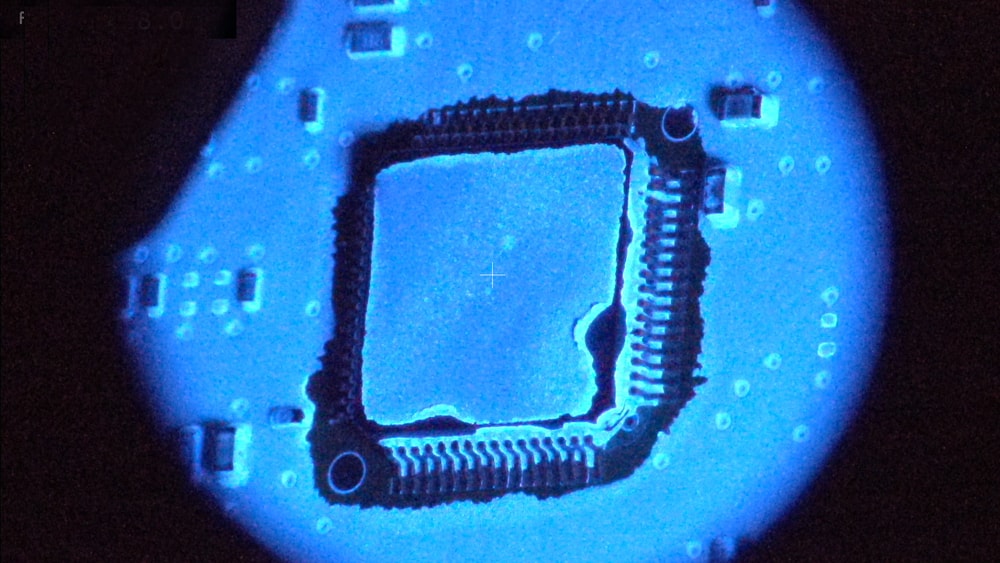

UV inspection of conformal coatings

Our UV illumination solutions, available with Mantis PIXO or Mantis ERGO, and EVO Cam II, give you a clear view of conformal coating, revealing a range of defects including thinning, pooling, bubbles and contamination, meeting the critical quality and safety standards of the aerospace industry.

Fidelity in the supply chain

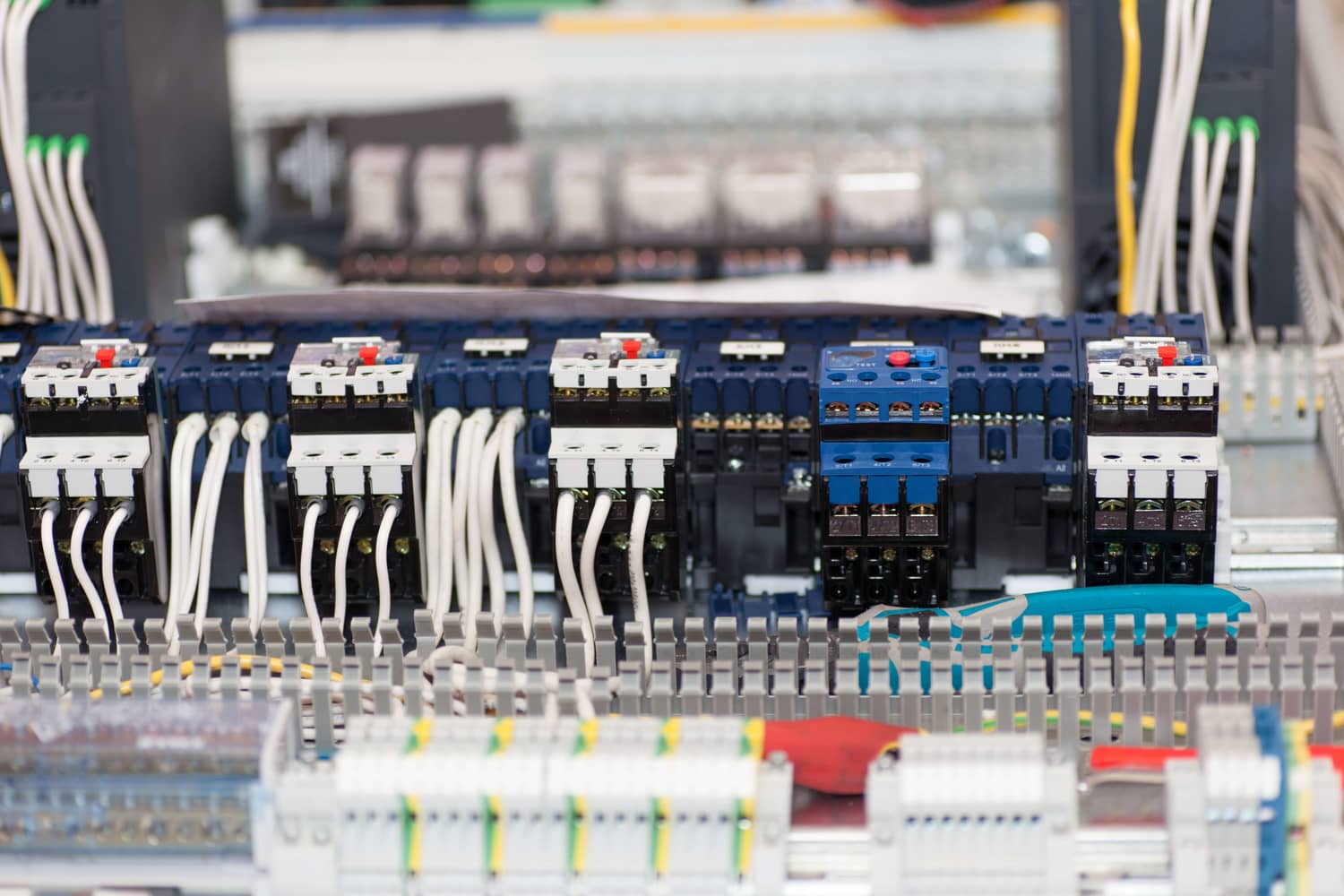

Vision Engineering’s inspection and measuring solutions help to preserve fidelity in aerospace supply chains by making it quick and easy to examine large volumes of components, of any material, from rivets through to complex electrical assemblies. 3D views let you see far more than ordinary 2D systems, and a range of software makes it easy to capture images, record measurements and create accurate documentation.

A coherent measurement and inspection strategy

Our range of contact and non-contact measurement solutions give you everything you need to streamline the inspection of any component from the simplest through to the most complex. PCBs, control systems, communications assemblies, safety equipment, radio components, and more, can all flow through the production line more quickly, into quality control and final inspection, fully documented and ready for despatch.

SUCCESS STORIES

Hawk is the ideal piece of metrology equipment for us. It is easy to use and flexible enough to gauge nearly all of our components. The reporting capability allows me to capture a data file for every component we measure, which is vital for component traceability.

We invested in the Mantis after our customer recommended the stereo microscope for specifically inspecting the firing pins. As the component parts are quite small, we were struggling to inspect the components by using our eyes alone due to their size and surface finish. Now we have the Mantis, we are minimising waste where we are able to clearly inspect the firing pins for a smooth surface finish.

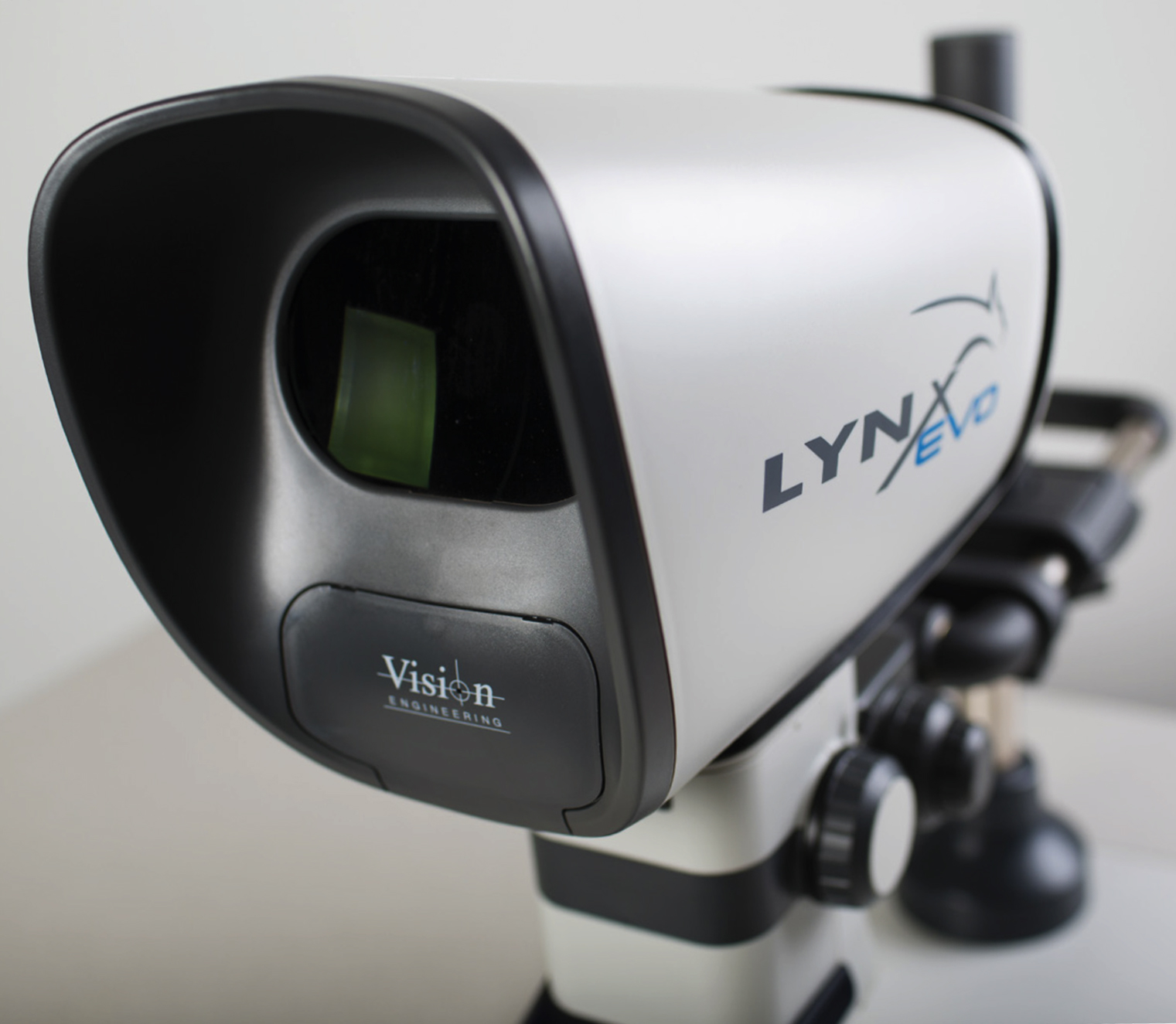

The oblique 360° viewer gives you that extra dimension and there is no other way we can do it. We get so much use out of the Lynx for our applications. It is invaluable and an absolute godsend

Lynx Evo

Work better, for longer, with this award winning ergonomic stereo microscope.

LVC

Extraordinarily capable, but surprisingly easy to use, Vision Engineering’s LVC400.