GASE Engineering Limited is a UK-based company specialising in precision manufacturing and engineering solutions across aerospace, defence, marine, telecommunications, and nuclear industries. With over 50 years of experience, the company has established itself as a leader in high-quality services, including machining, inspection, and fabrication.

The Challenge

One of their large telecommunications clients has strict requirements for components to ensure reliability and safety. These components are part of an underwater network. The remote and inaccessible nature of the installation makes repairs difficult, which means the inspection and assembly process needs an even higher degree of precision.

With components destined for an underwater network, precision isn’t optional-it’s essential to ensure reliability where repairs are nearly impossible

To meet these demands, GASE had to address these key factors during inspection and assembly:

- Fibre-sensitive products: components need to have smooth, damage-free surfaces. Even small can affect the fibre optics or electrical connections, leading to performance issues that are difficult to fix once installed.

- Magnification demands: Inspections require at least 10× magnification to identify small surface flaws, alignment problems, and debris that could interfere with connections or functionality.

- Electrostatic discharge (ESD) compliance: Given the sensitivity of the components, minimising the risks associated with electrostatic discharge (ESD) during the inspection and assembly processes is essential. Any static discharge risks damaging the electronics, resulting in costly repairs or failures.

These inspections required intense focus, so GASE needed a solution that offered improved precision while keeping operators comfortable during long periods of detailed work.

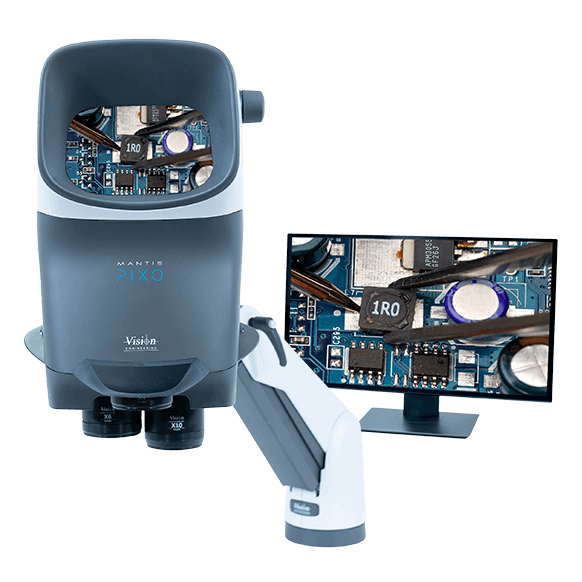

The Solution: Mantis PIXO

After exploring some options, GASE chose the Mantis PIXO inspection system, which their telecommunications client recommended based on their own positive experience with the solution.

Mantis PIXO delivers several key benefits tailored to GASE’s needs:

- Improved optical clarity: high-definition optics allows operators to inspect surfaces with exceptional clarity, detecting even the smallest imperfections, like metallic inclusions or scratches, which could compromise fibre optic or electrical connections.

- Magnification capability: the system’s 15 x magnification exceeds the required 10x, providing accuracy for identifying surface flaws, alignment issues, and potential debris that could interfere with connections.

- Electrostatic discharge (ESD) compliance: The system supports static-safe workflows, protecting sensitive electronics during inspection and assembly.

- Ergonomic design: The eyepiece-less design allows operators to work comfortably for extended periods without fatigue.

- Streamlined communication: Using the same system as their client simplifies discussions and ensures consistent standards during inspections.

The Results: Improved efficiency and enhanced communication

Mantis PIXO has delivered immediate improvements for GASE enabling them to meet the demanding needs of their telecommunications client. Its precision, reliability, and operator-focused design enhance inspection accuracy and efficiency while simplifying communication with their client.

The rollout across multiple sites highlights the scalability of the solution, positioning GASE to apply these improvements to other industries, such as aerospace and defence, ensuring they remain at the forefront of precision engineering solutions.

With the Mantis PIXO, we’ve improved precision, streamlined communication, and enhanced efficiency – all in one system.