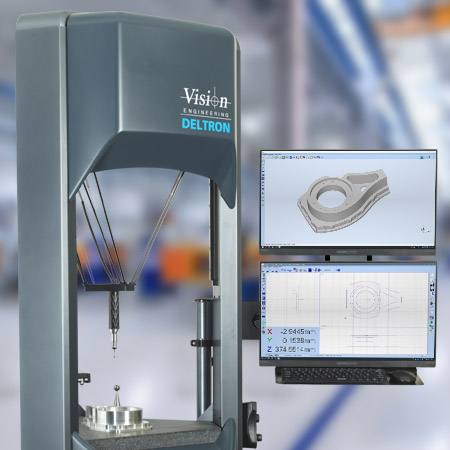

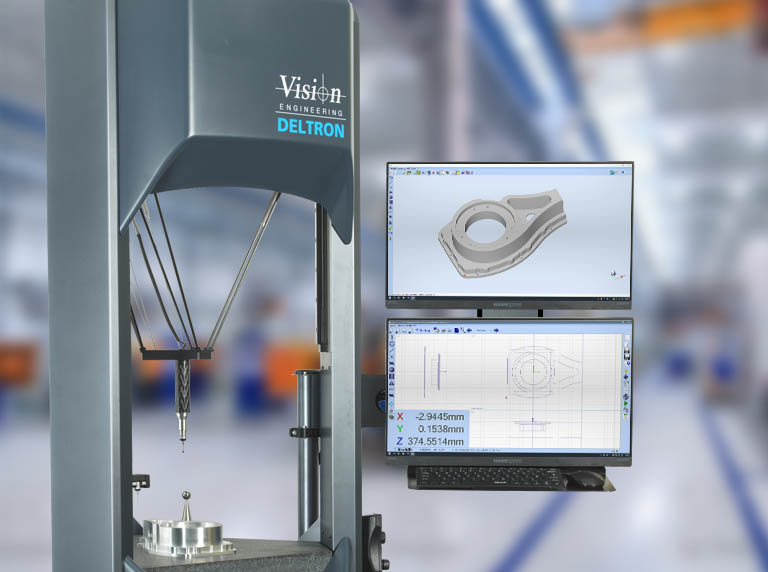

A robust CNC CMM with compact footprint for high levels of measurement accuracy.

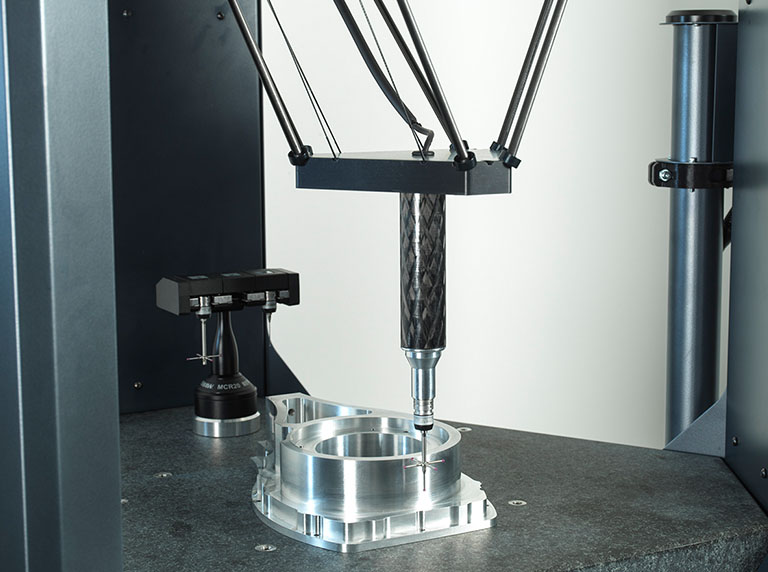

For those with limited shop floor space, Deltron is a robust and accurate CNC coordinate measuring machine, combined with compact footprint, but with substantial construction to ensure stability. This unique combination is only made possible by its delta mechanism incorporating carbon fibre rod construction, and well developed software control delivering high levels of measurement accuracy and repeatability.

Smooth, fast operation.

Deltron features fully sealed recirculating bearings, delivering four key benefits – no dirt ingress, no gearbox, no compressed air requirement and smooth, fast operation. Together these deliver exceptional accuracy, simplicity and reliability. Scale resolution of 0.1 μm and volumetric accuracy of (2.6+0.4L/100) μm combined with weight-saving carbon fibre arms deliver a high level of confidence in the measurement output – speed and accuracy you can rely on.

Always accurate

Deltron’s delta mechanism, precision mechanical bearings and built-in temperature sensors provide the stability and accuracy required from a precision measuring system, even when the ambient temperature is not controlled. This unique configuration ensures that fast and accurate measurements are maintained at all times.

520 mm x 300 mm

measuring volume

(dia. x height)

Fully Automated

3-axis CNC control

Always Accurate

ambient temperature compensated

Standalone or integrated

Deltron’s leading edge design combines a compact footprint with easy accessibility and surprisingly large measurement volume. As the system has no air bearings and both part and ambient temperatures are compensated, Deltron can be positioned exactly where it is needed. It is at home working alongside machine tools on the shop floor.

Use it standalone, with material handling systems, or integrate into automated manufacturing lines for in-process measurement.

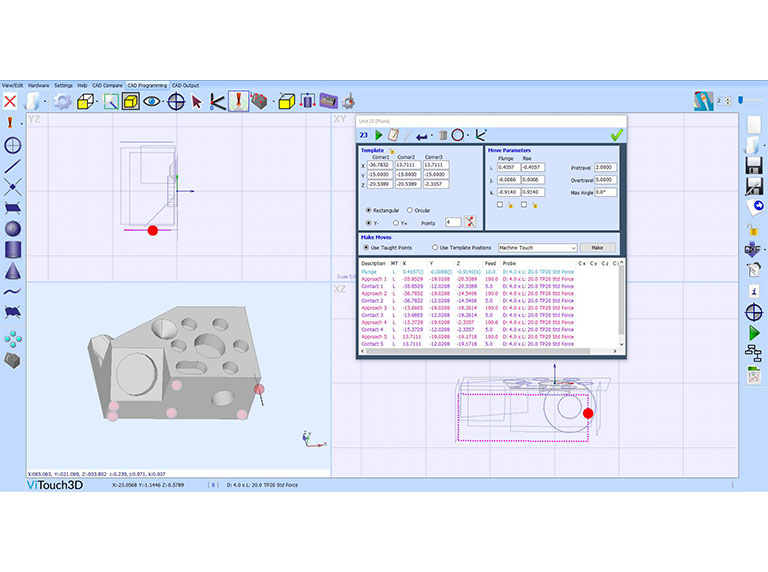

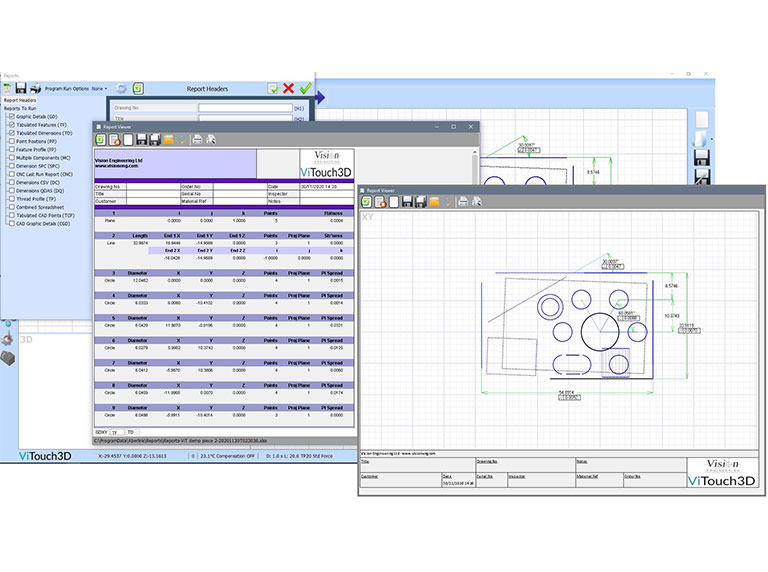

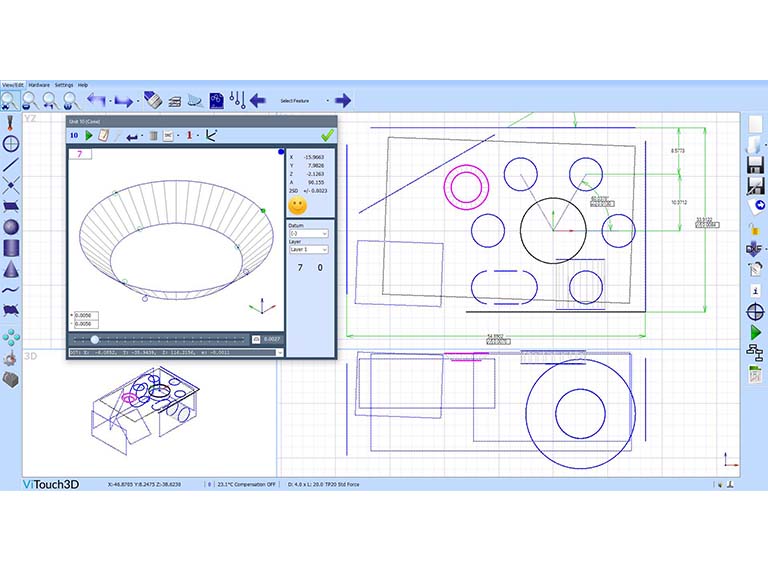

Intuitive software – you are in control

A powerful, yet easy-to-use user interface, increasing component throughput and minimising the learning period of new users. ViTouch3D software has a familiar, user friendly and intuitive interface, easy to learn for a range of operators. Its feature packed specification is suitable for occasional users or full time inspection professionals. Produce inspection reports easily, either as fully dimensioned graphical representations or tabulated reports that can be simply exported to Microsoft Excel.

Versatile

- Powerful interactive graphics window

- Automatic feature recognition

- Teach & repeat programming

- Run programmes from any point

- Engineering drawing GD&T

- Simple PASS/FAIL

- Free form curve inspection

- DXF data import/export

- STEP and IGES export

- No complex programming language

- Programming from CAD & Automation options

- Free software updates