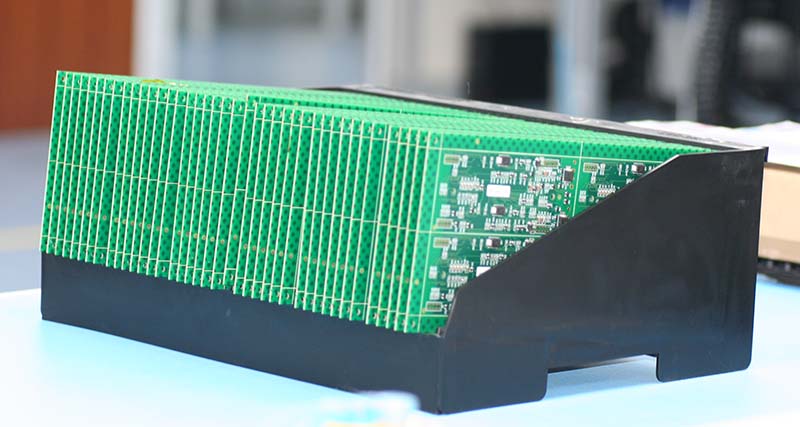

Newbury, Berkshire based Garner Osborne is a leading provider of printed circuit board (PCB) manufacturing and assembly services. The company is able to meet all prospective customers’ requirements, from small, low-cost or medium-sized orders, to design and prototyping or large scale offshore manufacture.

Now in its 29th year of operation, the expertise of Garner Osborne’s dedicated staff and the use of first-class manufacturing, assembly and inspection facilities has enabled the business to gain a reputation as a technical leader in the field of PCB production. In addition to several other equally demanding industries, Garner Osborne serves the medical, aerospace, automotive and broadcasting sectors.

Due to the critical functions Garner Osborne’s PCBs perform, quality checks are performed throughout all stages of manufacture and assembly. In addition to these intermediate checks, 100% final inspection is carried-out to ensure that every PCB meets customers’ requirements.

PCB assembly and inspection tasks

As electronic components are getting ever smaller and PCB assemblies are becoming more complex, a search was recently made for an advanced vision system that could cope with these challenges.

Having been impressed with previously purchased Vision Engineering products, such as the company’s Mantis microscope, Garner Osborne CEM Operations Director, Steve Honeybun was interested to hear about the high-profile launch of Vision Engineering’s unique DRV-Z1 (Deep Reality Viewer). The DRV-Z1’s cutting-edge 3D vision capabilities, the quality of the images and the ease of operation proved perfect for a range of demanding PCB assembly and inspection tasks.

With its unique ability to generate a digital stereo 3D image, the DRV-Z1 provides a comfortable and natural view of the subject. Creating an image using innovative optical and digital configurations, the revolutionary new offering delivers a 3D view with sharp details, vivid colour and excellent contrast.

A long working distance, large field of view and wide zoom range renders the DRV-Z1 suitable for countless applications and supports precise hand-to-eye co-ordination and the use of tools.

The DRV-Z1’s ergonomic design enables operators to maintain good posture and to enjoy fatigue free working, helping to improve productivity and work quality.

The DRV-Z1 is the first 3D stereo digital display that allows remote viewing, capture and sharing of the image. The ability to share live 3D images in real time across networks creates completely new opportunities for collaboration between customers, colleagues and suppliers.

Reducing PCB scrappage levels

Garner Osborne CEM Operations Director, Steve Honeybun enthused:

“Garner Osborne is certified by various national and international bodies within the industry and we hold numerous accreditations. We constantly strive to meet the highest PCB quality, assurance and testing standards for quality and service in all areas of our business. Our newly acquired ability to view PCB’s in 3D under magnification has further improved the efficiency of our assembly and inspection functions.

“For instance, now our operators don’t need to tilt a PCB to view its solder joints. Also, the addition of a free standing flat screen allows several operators to view a board together and to discuss their observations. As the DRV-Z1’s controls are so easy to use, following the short training course given to our operators, they became adept at the use of the DRV-Z1 on the day it was installed.

“As a result of its generation of high-resolution 3D images, the use of our DRV-Z1 is now helping to ensure the quality of our PCBs and assisting us in reducing our already low rework and scrap levels.”

“It is proving particularly useful for verifying first-offs where we require a greater level of clarity related to possible design/process issues, so that we do not end up with unnecessary and costly rework.

“Due to the quality of the 3D images the DRV-Z1 provides and its large field of view, as well as improving the accuracy of our tasks, it has increased the speed and efficiency of our work.

“In addition to the advantages the DRV-Z1 has provided to our assembly and inspection functions, as the welfare of our staff is one of our most important considerations, it is a major benefit that it also delivers a fatigue free operator experience.”

Advanced inspection aids are becoming essential

“The DRV-Z1 has also given us an enhanced means of communicating, for instance, when required, we are able to capture sharp PCB images and send them to our customers for clarification. Given the DRV-Z1’s prominent position on our shop-floor and its unique ability to present magnified 3D images of PCB’s, it is the first piece of equipment our existing and prospective customers see when they visit our Final Inspection area.

“We always demonstrate its capabilities to our visitors, and it has been very well received by all who has viewed the remarkable images it delivers. Manufacturers of advanced PCBs know that meeting the quality expectations of customers is vital to their success. Identifying PCB shorts, PCB voids, opens, misalignments and solder integrity of area-array chip packages is crucial, therefore the use of advanced inspection aids, such as the new DRV-Z1, is becoming essential.”

Vision Engineering’s microscope and metrology systems

Headquartered in Send, Surrey, Vision Engineering have been involved in the design and manufacture of world leading Stereo Microscopes for over 60 years. Engineers and scientists worldwide use the company’s high-quality systems for a wide range of inspection and measurement applications across a wide range of industries. Renowned for pioneering optical design, Vision Engineering’s microscope and metrology systems perform to the highest standards.